Ukuxuba kuhlulwe kumxube womatshini kunye nokuxuba ngesandla.Okwangoku, i-mixers enyanzelekileyo okanye i-mortar isetyenziswe kwishishini ukuxuba izinto, kwaye ukuxuba ngesandla akusetyenziswanga Izixhobo kunye nezixhobo: ukunyanzeliswa okanye umxube wodaka, iibhakethi, izikali, i-vibrators, ifosholo zesixhobo, iitroli, njl.

Ukusetyenziswa kwamanzi okwakhiwa kusekelwe kusetyenziso lwamanzi olubonakaliswe kwiphepha lokuhlola umgangatho webhetshi yeemveliso, kwaye iphunyezwe ngokungqongqo ngokuhambelana nemigangatho yokufezekisa umlinganiselo ochanekileyo.

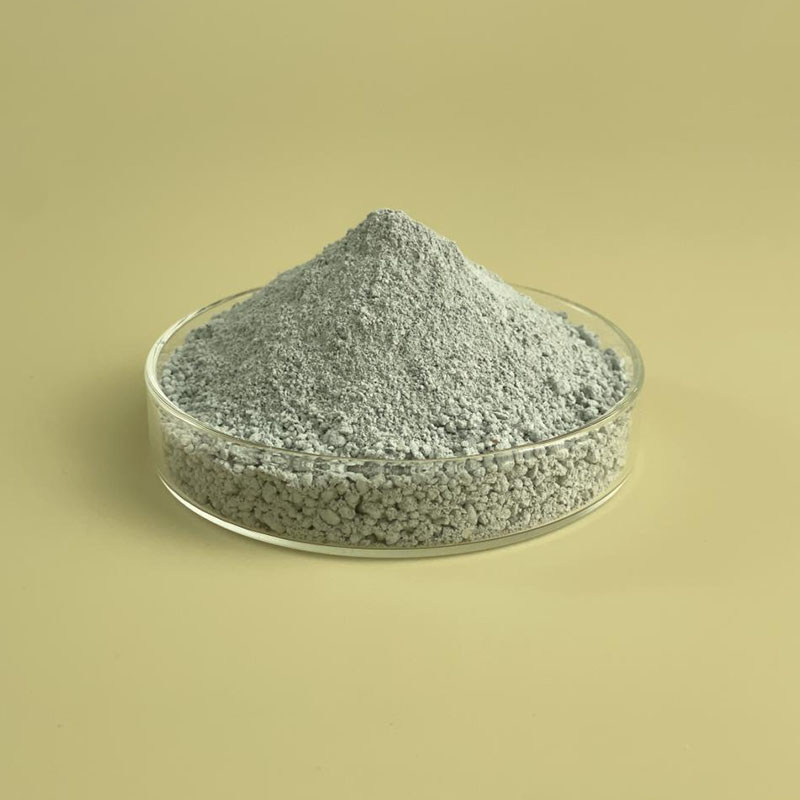

Ukuxuba: Xuba yomise kuqala kwaye umanzi.Beka izinto ezininzi kwi-mixer kwaye uyomise imizuzu eyi-1-3 ngokulandelelana kwesikhwama esikhulu kuqala kwaye emva koko isikhwama esincinci ukuze sidibanise ngokulinganayo.Ubunzima bomxube ngamnye bunqunywe ngokuhambelana noomatshini kunye nomthamo wokwakha;ngokobunzima bezinto eziphathekayo, amanzi afunekayo kumxube ngamnye alinganiswe ngokuchanekileyo ngokusetyenziswa kwamanzi achaziweyo, ongezwe kwizinto ezomileyo ezixutywe ngokulinganayo, kwaye avuselelwe ngokupheleleyo.Ixesha alikho ngaphantsi kwe-3min, ukwenzela ukuba ibe ne-fluidity efanelekileyo, kwaye ke izinto eziphathekayo zinokukhutshwa ukuze zigalelwe.